India needs a Strategic Shift in its Policy on Quality to achieve 'self-reliance'

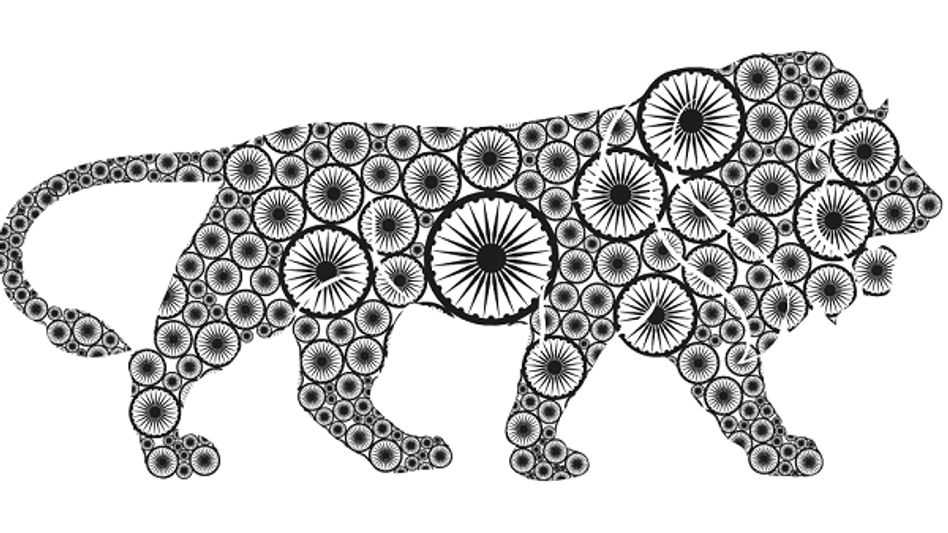

Source: CleanPng

Source: CleanPngThe recent Indo-China faceoff at Galwan Valley in Ladakh has led to a nation-wide public campaign to boycott Chinese goods. This boycott comes in against the backdrop of two massive campaigns of the Government of India – Aatmanirbhar Bharat Abhiyan, which aims to make India self-reliant and the Make in India campaign, the objective of which is to turn India into a world manufacturing hub.

Although there lies no doubt regarding the objectives of these campaigns, the primary issue lies in its viability. One of the key concerns in this regard is assuring quality as per global standards. To achieve this, there has to be a policy shift in determining quality in India’s manufacturing sector.

The general understanding is that quality is what the customer wants, or in other words, quality is when a product is free from deficiency. There are various tools and methods utilized by the companies to ensure quality in products. Each of these methods differ significantly in their approach towards ‘quality’.

Quality Control (QC) is an inspectorial attitude to quality, whereby designated supervisors will inspect and certify quality, and the duty of deficiency free production lies with the production department. Quality Management (QM) is a more holistic process that includes strategic decision making and resource allocation for teamwork building, continuous improvement and built-in quality.

Dr. APJ Abdul Kalam in his speech at CII Quality Institute said, “The best way to achieve quality is to build it into the design.”1 Quality Management tries to achieve the very same objective. Rather than post production inspection, its focus is end-to-end intervention and continuous improvement of quality and systems. The Japanese concept of Total Quality Management provides a broad set of guidelines on how to implement these ideas.

Need for ‘Continuous Improvement’ in India

The year 1991 was a watershed moment in India’s history as it was the formal declaration of globalisation in India. Evidently, this is also the time when Indian companies made a run for ISO 9000 standards. Later, during the turn of the 21st century, companies voluntarily made a transition to Total Quality Management. In fact, Indian companies were quick in response to the needs of globalisation and wasted no time in adopting the best quality systems.

Also read: Delhi seems like a Distant Dream for students post corona pandemic

India has the largest number of companies, outside of Japan, that have been recognised for excellence in quality2. Industries had to evolve from QC to TQM to keep up with the global competition. But should this be the end?

In the recent past, questions were raised about the quality of Personal Protective Equipment (PPEs) exported from China. Quality, hence, is not a one off game. It must be continuously revised, and worked upon.

Quality is also a game of perception. Researchers have found that country of origin is as important an external cue for product quality, as any other parameter3. Our Southeast Asian neighbours such as Vietnam are transitioning to a more quality concerned nation, where Quality perceptions and considerations drive most of the Vietnamese consumer’s purchasing preferences4.

A fundamental bottleneck to developing quality culture in India is that quality is presumed to be the sole responsibility of the industries. But history tells us that Industries have the ability and will to evolve and adapt, but the structural deficits in relation to quality within the government have largely remained the same. How do we equip the government to change with the tides of time?

The current practices of Government are inspectorial in nature and QC is the adopted technique. A change in attitude is the need of the hour. The first logical step is to move towards Quality Management. It is also pertinent to inform at this stage that QC remains a sub-part of QM, and adopting QM does not necessitate the state to abdicate its inspectorial duties.

The government has to plan and allocate resources for improvement of quality across all sectors in India. This naturally converts the role of Government from an Inspector to a stakeholder in Quality. It must be willing to accept the role of guide and a guarantor of quality for India.

The Road Ahead

Trade Policy 2015-20 was set to expire in the current year, but in the wake of a global pandemic, its applicability has been extended upto March 31st, 20215. This provides us with ample time and an opportunity to include a Chapter on Quality in the subsequent Trade Policy.

Empirical results confirm a theoretical prediction - rich countries tend to import relatively more from countries that produce high-quality goods6. Quality is not only about standards, but also about perception. To change perception, the foremost work is to have our trade policy and all Industrial policies reflect on the value of quality on par with other aspects.

Although, it is equally important for the Industrial Policies for each sector to have measurable targets of quality, rather than vague reference to 'high standards of quality'.

The focal point of Industrial Policy must not only be large corporates, but micro, small and medium enterprises (MSMEs) as well. There is no meaning to quality culture if these values do not percolate down to MSMEs. MSMEs conduct significant B2B transactions, and are responsible for a considerable share of primary and intermediate inputs for larger industries. There are two challenges for built-in quality in MSMEs – skill and technology.

Technology upgradation through subsidised loans and conditional grants, and skill enhancement is only way ahead to develop quality culture in these industries. Technology is a priority as it still remains the key deficit of MSMEs.

The Draft National Resource Efficiency Plan is an ambitious plan which aims efficient use of natural resources with minimum negative impact on the environment. It sets guidelines and standards regarding quality of secondary raw materials, along with assuring incentives to the industries. This is a good place to start with, where quality, and not only quantity, is rewarded. Such an enabling environment needs to be reflected in our laws relating to quality as well.

Nearly half a century ago, the Export (Quality Control and Inspection) Act, 1963 was introduced aiming at quality control and pre-shipment inspection in case of exports. The concept of assessing quality has seen tectonic shifts worldwide overtime. While the Act primarily focuses on inspection, and penalising in case of default; from a quality management perspective the need is to ensure quality at all stages of production - from raw materials to finished goods. The incumbent role of state needs re-adjustment, and the Government must trade away the fear of penalty and re-orient its policy towards the goal of facilitating and enabling quality; a step in the direction of quality management.

Conclusion

Henry Ford, the pioneer of Assembly manufacturing, once said, “Quality means doing it right when no one is looking”. Industries need to be more vigilant and forthcoming with their quality standards and regulatory compliance if the exercise of Quality Management is to be a success. The spirit of cooperation works well only when all strings are tuned to the same scale. In lines of safety culture and safety first, we also need to work towards a quality culture. This is only possible when all stakeholders work towards developing built-in quality, which in turn is possible only when resources and planning indulges quality on par with production.

About the authors

Abhijit Rajkhowa is a Mechanical Engineer, with interest in Public Policy. He has previously worked as Assistant Quality Manager at Tata Motors Ltd.

Abhishek Chakravarty is an Assistant Professor of Law at Sai University and Faculty at Daksha Fellowship. He specialises in Environmental Law. He has also previously worked in the public policy sector.

The opinions expressed are that of the author

Readers like you make Inside Northeast’s work possible.

To support our brand of fearless and investigative journalism, support us HERE.

Download:

The Inside Northeast app HERE for News, Views, and Reviews from Northeast India.

Do keep following us for news on-the-go. We deliver the Northeast.

Copyright©2025 Living Media India Limited. For reprint rights: Syndications Today